Your 3D printer might have a very high resolution but that does not mean that your prints will be precise or accurate. Understanding the meaning of tolerance is imperative for individuals who want to achieve meaningful 3-dimensional print performance regardless of the application.

In 3D printing, you have to ensure that your prints have the right appearance. Problems are unlikely to occur during the printing, but they occur in the curing part. By mitigating the problems, you will come up with a print that looks nice and smooth after the post-processing.

You have to set your 3D printer so that it can provide you with the best results. Almost any printer can improve the smoothness of a print to some degree, but naturally, you will have to go for some of the most expensive printers to achieve that.

If your printer can provide good finish 3D prints, you will do less post print work. The printing material you select also affects the quality of your prints. Before printing, you will have to ensure that your print materials are in the right shape and you should identify their shrinkage percentage.

If you need great looking prints, you will have to start with the filament. A quality filament will provide great looking prints and after sanding your 3D prints will look smoother. To ensure that your prints are of the right size, you should always consider the tolerance before you start printing.

What are Tolerances?

What are Tolerances? (source)

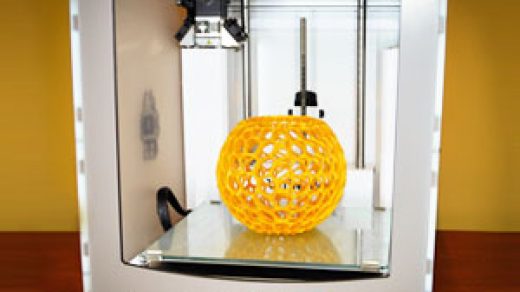

Tolerances depict the deviation from the specific value you expected or the acceptable value. Tolerances are important in almost every industry.

In the food industry, for example, distributors label the large containers as 1000 g +/- 5g. The +/-5g shows tolerance, which describes the acceptable deviation amount.

In the 3D printing world, the printing machines have particular tolerances, which is also the case to expect in the manufacturing industries.

Your prints might deviate slightly from the real dimensions. If the tolerance is tighter, you should know that the dimensional accuracy is consistently high.

You are the person to define the tolerance, which will, in turn, define how the precise the print will be. As the person doing the printing, you will have to decide the wiggle room you need in the print.

The acceptable variance should be close to the actual measurement. That will depend on your project. A quick example, components with dynamic mechanical assembly will need tighter tolerances compared to items like the simple plastic enclosures.

When designing tolerance, you will have to be accurate. But if the tolerance is large, you will have adequate room during your design.

Does Tolerance Matter in 3D Printing?

Does Tolerance Matter in 3D Printing? (source)

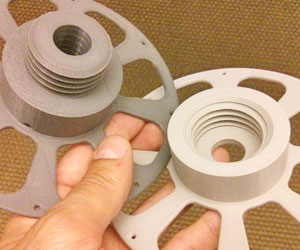

In 3D printing, tolerances are crucial when creating parts that have to fit together perfectly. For example, in the FDM 3 dimension printing, the printers have to remain alert because the tolerances are likely to be loose.

If you already know the tolerances of your printer, you will be able to design parts accurately.

You have to create the parts with adequate space between them as a way of catering for any potential dimensional deviations.

People who do not understand the purposes of tolerances in 3D printing make parts that fit poorly and the support structures might adhere to the prints completely.

When thinking of tolerance in the 3D printing world, you will have to identify your specific needs. A quick example, precise-but-inaccurate printers are a better choice when creating some applications.

The low-cost FDM (fused deposition modeling) machines produce less accurate prints, but they are ideal for educators teaching students about the technology of 3D printing. The print should match the CAD design of the students.

Knowing that a printer will work consistently as the producer promises and produce the desired results, within the set tolerance is important for a successful experience.

Consider 3D Print Material Shrinkage

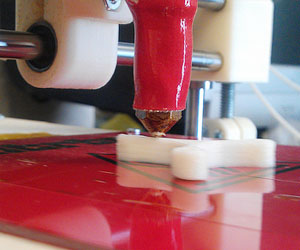

Three-dimensional printing involves additive processes, which means that the printer creates models layer after layer. Every layer will introduce an opportunity of inaccuracy, and the formation of layers affects the repeatability or precision of each layer.

A quick example, in FDM 3D printing, the machine extrudes the layers from a nozzle. The nozzle does not have the ability or control the user needs to attain intricate details that some other technologies offer. The models might show inaccuracies around the complex features.

In stereolithography (SLA) printing, the liquid resin cures to form a layer after layer with the help of a precise laser, which facilitates the development of fine details.

The machines also achieve great results repeatedly. Similarly, the selective laser sintering (SLS) 3-dimensional printing relies on laser precision to fuse powdered nylon into models.

The specs of 3D printers alone cannot represent the accuracy. A common misrepresentation of accuracy in 3D printing is the XY resolution description – most people see it as the accuracy. For DLP (digital light processing) printers, XY resolution refers to the size of the projected pixel. Most printers use the size of the projected pixel as the overall accuracy. The data can have a great effect on the accuracy of the print.

Different printing materials have different shrinkage percentage. Therefore, the material you use will determine the accuracy level of the resulting model. Some materials can even warp after cooling. In the post-curing stage, the print might shrink.

That is normal in almost every form of 3D printing, particularly with DLP and SLA technology and you will have to consider that during the design process.

3D printer manufacturers offer software programs that compensate for the shrinkage to ensure that each post-cured print is dimensionally accurate.

The 3D print will need more attention than the printing machine itself and the post-processing tools contribute to the results. Integrated systems that work together offer reliable results.

How to Test 3D Printer Tolerance?

How to Test 3D Printer Tolerance? (source)

To test for the tolerance of a 3D printer, you will have to start by calibrating your printer and the extruder properly. One of the tools that will provide you with great results is the calibration cube.

After you are ready to start printing out your models, you just need to print 3-5 of the dimensional accuracy tests or the calibration cubes. Measure the printed models within the same environment. Record the model’s orientation and then record the measurements – the X, Y and Z measurements.

After recording the direction, you will have to subtract a small measurement from the large measurement. The number will be a good beginning point for designing clearances.

The printer’s tolerance will be around +/- 0.5 of your clearance value. A quick example, you are likely to get 19.9 mm, 10.1 mm or 20.1 mm for your cube’s Y dimensions.

To get the clearance value, you have to subtract the highest value from the lowest (20.1-19.9=0.2 mm) and the tolerance +/- 0.1mm.

SLA has a higher tolerance than other 3D printing technologies. Unlike the machined accuracy, the accuracy in SLA 3D printing is close to that of fine machining and standard machining.

The more compliant SLA printing materials have wide tolerance zone than the rigid materials. If the user is printing parts for use in assemblies, proper tolerance, less processing time and ease of assembly are important. Proper tolerances also reduce the cost of iteration.

Maker’s Muse Tolerance Gauge

If you need to get the clearances directly, particularly if you need to fit 3D printed parts to other parts, the Maker’s Muse Tolerance Gauge is a better choice. The tool is among the effective clearance test tools and comes at a very low price.

If you need a free version of the tool, you will need to follow Maker’s Muse on their YouTube channel. The tolerance gauge will help you to set the clearances when completing designs.

How to Improve 3D Print Tolerance?

In the 3D printing world, the room for growth exists in every situation. If the print results are unsatisfying, you should try the following tips. They will help you improve the 3D print tolerance.

Monitor the movement of your components

Deteriorating components of your 3D printer can make your prints less precise. The belts of your 3D printer should tight and the wear on bearings and rods should be minimal. If that is not the case, replace or tighten the parts. Do not try that unless you have contacted the manufacturer for guidance.

Use better filament

The cheap filament available in the market has poor tolerance that can cause extrusion irregularities. Printing irregularities will definitely translate to uneven surfaces on every print.

Calibrate properly

You will have to calibrate the printer and the extruder properly before you retest for tolerances. If the tolerances vary significantly, you should take that as an indication of very poor printer calibration. To measure the variance accurately, use the calibration cube.

Conclusion

Tolerances vary according to the machine, material, and the printing process. The SLA material requires 0.025 inches, while SLS and FDM processes require more than 0.030 inches wall thickness.

Polyjet demand more than 0.025 inches, but the soft durometer material have to be thick to withstand flexing and bending. Whether it is CNC milling, 3D printing or bagging chips, you should keep in mind that the machines involve slight inconsistencies. They produce parts with differing tolerances. That is why you will have to work to prevent that.